SERVICE Businesses Vacuum Coating Division

Overview

Ramtech has developed a RAM cathode for use in four face target sputtering method, which enables the deposition of high-quality thin film.

The RAM cathode features low damage, low temperature deposition, and a smooth surface with few pinholes and other defects.

RAM cathode is used in various fields such as perovskite solar cells and OLED. Our lab room is equipped with cluster sputtering system equipped with RAM cathode and is available for deposition tests on substrates supplied by our customers.

We will solve problems you face!

-

If you want a coat with minimal damage

-

If you want a coat with a smooth film surface

-

If you want a coat on a low-heat-resistance substrate

-

If you want a coat with few defects such as pin holes

Features

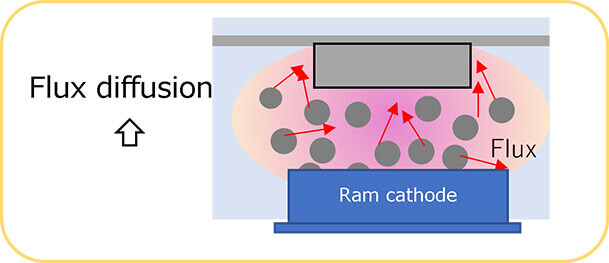

Achieve low-damage sputtering

In the conventional flat plate sputtering method, sputtering flux and recoil argon from the target collide directly with the substrate, resulting in very large damage during deposition.

By depositing the film with a RAM cathode, flux do not directly hit the substrate and the sputtering flux are uniformly rained down, so the film can be deposited with minimal damage.

High quality thin film deposition is possible

The sputtering flux scattered from opposing targets collide with each other, which promotes the refinement of the sputtering flux.

The uniform deposition of fine flux results in a smooth surface and the formation of a film without few pinholes.

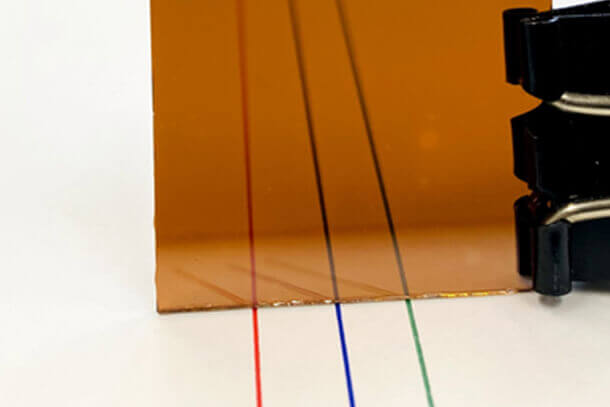

Realization of High Step Coverage

In conventional sputtering, the surface parallel to the target is the main deposition surface.

By changing the film deposition conditions with RAM cathode and using sputtering flux scattered diagonally, it is possible to effectively to deposition on the side surface with >85% thickness (compared to the film thickness) .

The RAM cathode can be used in a wide range of processes depending on the conditions.

List of devices

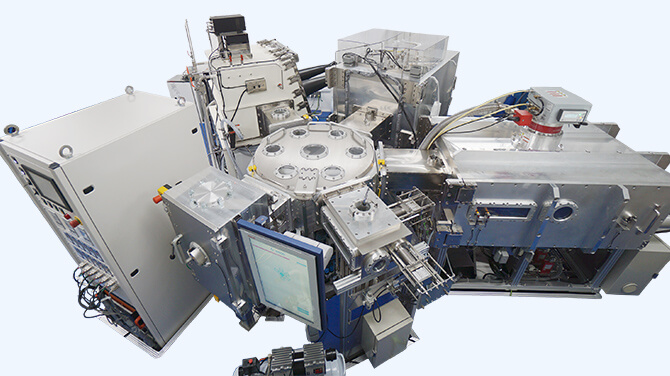

Cluster-type sputtering equipment

・Effective film formation range

200mm×200mm

・Equipment configuration

RAM cathode mounted sputtering chamber / Planer cathode mounted sputtering chamber / Conveyor center chamber / Load lock chamber / Glove box

・Film material

TCO (ITO etc.) / Metals (Cu etc.) / Metal oxides (NiO etc.) / C (DLC) / Others

Large-area vertical sputtering equipment

・Effective film formation range

300mm×100mm

・Equipment configuration

Vertical RAM cathode mounted sputtering chamber

・Film materia

TCO (ITO etc.) / Metals (Cu etc.) / Metal oxides (NiO etc.) / C (DLC) / Others

Related products

ITO(Indium Tin Oxide)

ITO (Indium Tin Oxide) is used as TCO (Transparent Conductive Oxide). RAM cathode allow the formation of low-damage, dense deposition that reduce device degradation.

Ram cathode is used in damage-sensitive devices such as perovskite solar cells and OLED display. Our proprietary system allows us to perform test deposition.

DLC(Diamond Like Carbon)

Ramtech has successfully developed a high hardness DLC that is difficult with planar sputtering method. Due to the characteristics of the RAM cathode, the surface is very smooth, and a high light transmission DLC film is achieved.

We perform test depositions using our own sputtering equipment.

Sputtering system with RAM cathode

In order to realize the full potential of RAM cathode, we are developing and selling sputtering system equipped with RAM cathodes.

Our innovatively designed sputtering system has a proven track record, having also been supplied to overseas research institutes and companies.