ABOUT What is KEIHIN RAMTECH Co., Ltd.?

KEIHIN RAMTECH’s strengths represented by

“R”, “A” and “M”

The “RAM” in RAMTECH stands for the concept of a Revolutionary Advanced Manufacturer.

Our core technology that has been passed down and accumulated since our inception to this day

will continue to be passed down person-to-person to the next generation and will be developed further.

REVOLUTIONARY

In film deposition, conventional planar sputtering has a high deposition rate but causes significant damage to the substrate, while opposed sputtering has the problem that the momentum of argon ions is weak, resulting in a slow deposition rate. In January 2016, we solved these problems by reducing damage to substrates by more than 60% using our proprietary technology (patent registered). We are convinced that our desire for “innovation” is our great strength and the path that leads us to create newer and higher quality products.

ADVANCED

Translated with www.DeepL.com/Translator (free version)

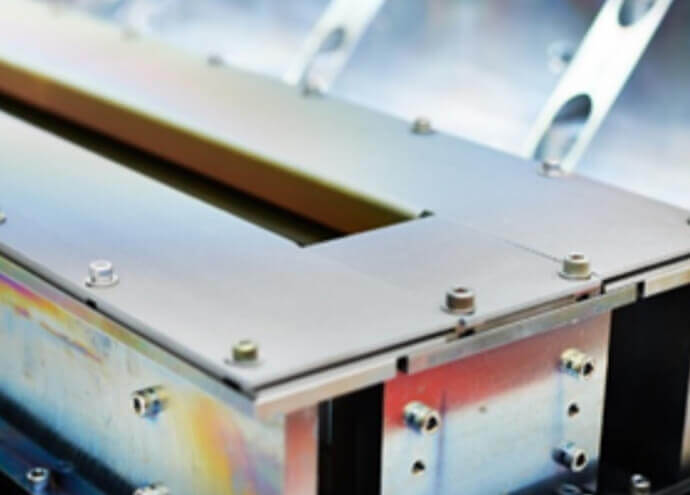

At KEIHIN RAMTECH, we introduced the FSW (friction stir welding) system earlier than most companies in Japan, and have accumulated a wealth of expertise in welding technology. We entered a licensing agreement with TWI in 2007 and have continued to achieve further technical developments. From pilot production by FSW to large-scale mass production, we can offer welding services in various materials such as copper, aluminum, magnesium, and iron. Offering a variety of technological solutions and support, we can be the perfect business partner for our customers.

MANUFACTURERS

Integration of the latest technologies and handwork by our team of competent engineers

At KEIHIN RAMTECH we have been contributing to a wide range of industries for more than 40 years since our foundation by continually incorporating the latest technology and equipment. This was made possible not only by means of the latest technology and equipment, but above all because of the skilled manpower we cultivated. For example, in FSW (friction stir welding), even if the material is difficult to bond, we identify and calculate the optimal parameters from dozens of combinations of rotation and feed speed of the welding tool. The shape of the welding tool, which is vital to FSW, is determined based on the abundant experience and knowledge of our engineers. As for machining technology, we provide the optimal machining accuracy (surface roughness, dimensional accuracy, flatness, parallelism, etc.) after carefully considering the desired end product as well as the completion of each part. We at KEIHIN RAMTECH believe that we can improve our design and development capabilities further only because of the accumulated technologies generated by the hands of our engineers. And thanks to the integration of the latest technologies and our people’s handwork, we have gained a reputation as a high-quality manufacturer along with trust from our customers around the world.