SERVICE Businesses Materials Division

Overview

Rotary sputtering cathodes can form coatings of oxide, etc. at a higher speed and have a higher usage rate of targets in comparison with conventional planar sputtering cathode. By using rotary sputtering cathode as dual-cathodes, target change-out frequencies can be drastically reduced. We are responding to various customer needs by applying our unique technology and establishing a stable supply system for rotary targets.

We will solve the problems you are facing!

-

A wide range of materials (ceramic, rare metal, metallic materials, etc.) can be supplied.

-

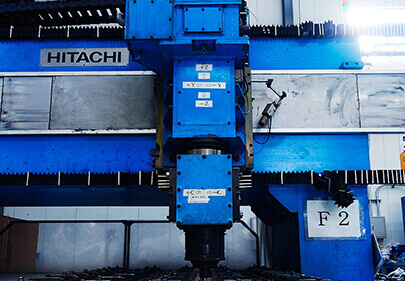

We have multiple production bases and can handle a wide range of tasks, from prototyping to mass production.

-

We have an integrated production system that covers everything from material procurement to processing and finishing

Features

High-quality finish for rotary targets.

We also provide a comprehensive after-sales service.

The materials we handle include not only metals, but also materials such as Si and NbOx that cannot be processed by cutting alone. For this reason, we have installed dedicated polishing equipment for rotary targets within the company to ensure a stable supply for customers.

Rotary sputtering targets

For thin-film materials that are indispensable as wiring or antireflection coating material for LCD panels, we customize target materials according to your needs. We also offer a wide range of other products such as NbOx, Cr, and AZO.

Our track record

Planar sputtering targets

As LCD panel sizes increase, we are able to handle up to generation G10.5.

We also offer a wide range of other products, such as Al/Ti. We will happily respond to your requests regarding specific details and specifications.

Planar targets(Cu)

| Chemical Composition | Cu |

|---|---|

| Molding process | one-batch forming |

| Density | 8.9g/ cm3 |

| Purity | 99.99% |

| Maximum Rotary size | 4000mm |

Maximum Impurities content

(Unit:ppm)

| Pb | 0.001 | P | 0.0003 | Sb | 0.001 |

| Fe | 0.001 | S | 0.0018 | Ag | 0.003 |

| Ni | 0.001 | Se | 0.001 | 0.001 | 0.001 |

| Zn | 0.0001 | Te | 0.001 | ||

| O | 0.001 | As | 0.001 |

Rotary sputtering targets

For thin-film materials that are indispensable as wiring or antireflection coating material for LCD panels, we customize target materials according to your needs. We also offer a wide range of other products such as NbOx, Cr, and AZO.

Rotatable Si Target

| Chemical Composition | Si |

|---|---|

| Molding process | HPS |

| Density | 2.33g/cm3(≧95%) |

| Purity | >99.95% |

| Maximum Rotary size | 4,000mm |

Maximum Impurities content

(Unit:ppm)

| Cr | 10 | Mo | 20 | V | 20 |

| Ni | 40 | Cu | 50 | O | 6000 |

| Fe | 50 | Ti | 30 |

Rotatable AL Target

| Chemical Composition | Al |

|---|---|

| Molding process | one-batch forming |

| Density | 2.7g/cm3 |

| Purity | 99.99% |

| Maximum Rotary size | 4000mm |

Maximum Impurities content

(Unit:ppm)

| Fe | 25.1 | Mn | 1.28 | Mg | 3.37 |

| Si | 29.6 | Cr | 1.26 | Ni | 1.41 |

| Ti | 1.33 | Cu | 22.1 | Zn | 1.85 |

Rotatable Cu Target

| Chemical Composition | Cu |

|---|---|

| Molding process | one-batch forming |

| Density | 8.9g/cm3 |

| Purity | 99.99% |

| Maximum Rotary size | 4000mm |

Maximum Impurities content

(Unit:ppm)

| Pb | 0.001 | P | 0.0003 | Sb | 0.001 |

| Fe | 0.001 | S | 0.0018 | Ag | 0.003 |

| Ni | 0.001 | Se | 0.001 | Mn | 0.001 |

| Zn | 0.0001 | Te | 0.001 | ||

| O | 0.001 | As | 0.001 |

Related products

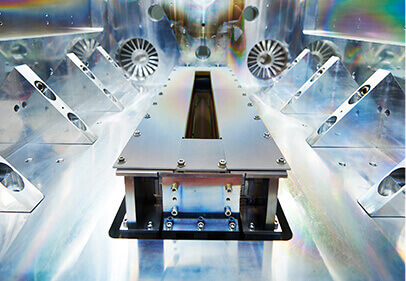

Backing plates for FPD

There is growing demand for backing plates with the expansion of the flat panel display market. Our backing plates are manufactured using unique technology and provide stable sputtering thanks to their large size, excellent flatness, and high cooling efficiency, making highly regarded by customers all over the world.

Backing plates for semiconductors

We supply a wide variety of products such as copper, Corson alloys, and chrome copper in order to support the rapid developments in integration in recent years along with the increasing speed of devices.

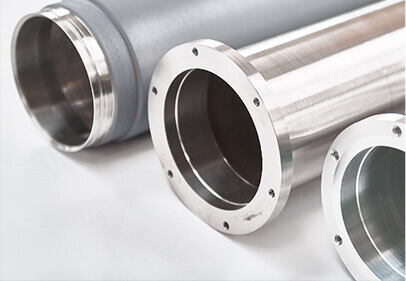

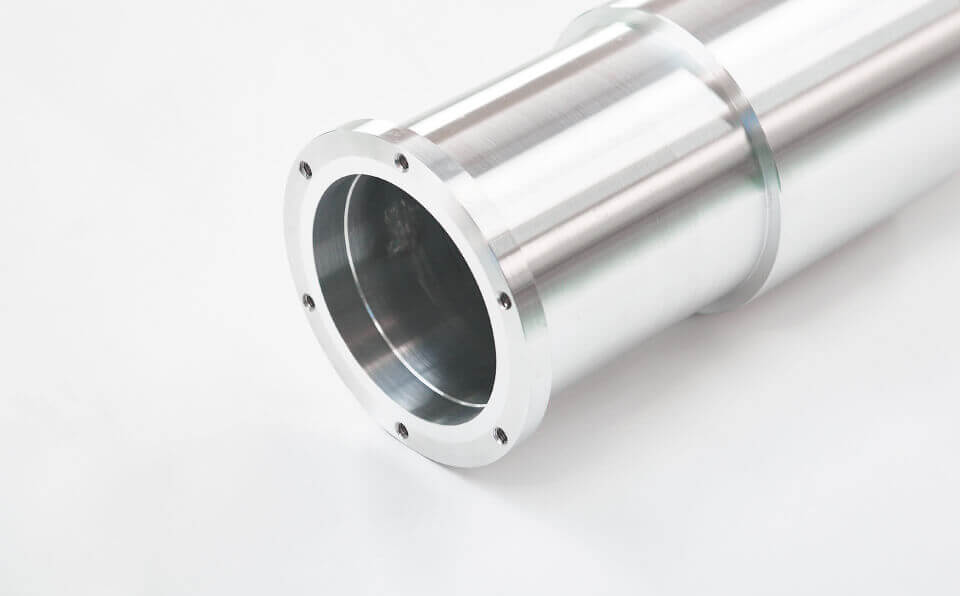

Rotary backing tubes

Rotary sputtering cathodes can form coatings of oxides etc. at a higher speed and have a higher usage rate of targets in comparison with conventional planar sputtering cathodes. By using rotary sputtering cathodes as dual-cathodes, target change-out frequencies can be drastically reduced.

We produce backing tubes for rotary sputtering equipment. Supported materials include Ti and SUS.