SERVICE Businesses SSW (Synchronized Stir Welding) Division SSW (Synchronized Stir Welding) Division

Overview

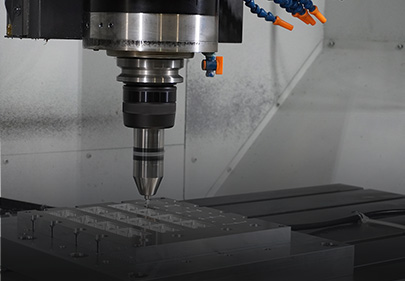

We have developed the SSW that goes beyond the performances of conventional FSW by simply attaching it to the ATC of an existing milling machine without the need for a dedicated FSW machine or FSW multifunction machine.

SSW Tool Holder does not require a tilt angle, and offers a significantly “high-speed, high-strength, low-temperature welding” compared to a conventional FSW technology.

Taking advantage of the features of the SSW Tool Holder, it is used in various fields from the EV automotive industry to the aerospace industry.

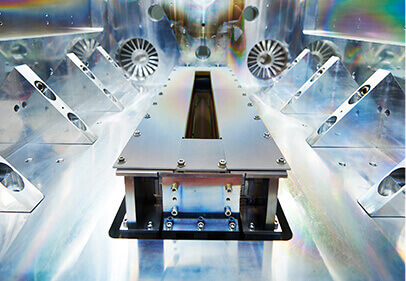

Our R&D center is equipped with a machining center with the SSW Tool Holder, We can provide a modeling for welding tools and propose welding parameters according to your requirements.

We will solve the problems you are facing!

-

Want to introduce a dedicated FSW machine into production lines,

but the cost is prohibitive and making space for it is difficult -

Want to reutilize current machining centers and NC milling machines for carring out FSW process

-

We want to improve FSW

productivity -

Condition setting for FSW is

difficult -

Being capable of a wide range

of joining structures

RAM FORCE

Synchronized Stir Welding Solutions

Key Concept

- high speed welding

- high strength

- low temperature

Key Features

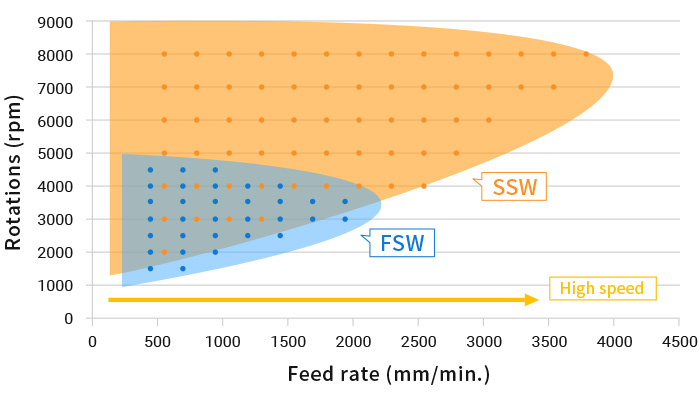

high speed welding

Comparison of FSW and

SSW welding parameter ranges

Material:A6061-T6

Compared to FSW, SSW is capable of welding at approximately twice the speed in the high-speed range.

The wide welding range also makes it easy to find the optimum welding conditions, and at the same time, the occurrence of welding area defects is minimized, making it possible to obtain a superior range of setting conditions.

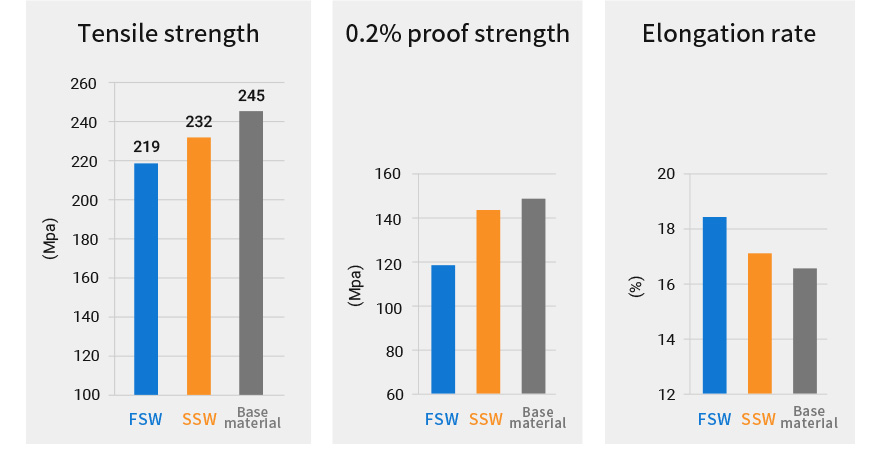

high strength

Butt joint strength

Material:A5052 plate

(mechanical properties)

The tensile strength of the base material is 245Mpa, while that of the SSW is 232Mpa, which means an astonishing 95% welding efficiency has been achieved.

The elongation is also nearly the same as that of the base material, and the strength is greater than that of regular FSW.

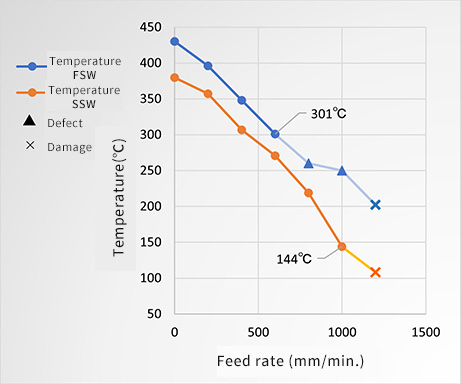

low temperature

Measurement & comparison

of FSW and SSW welding temperatures

Material:A6061-T6

With FSW, internal defects due to insufficient heat input begin to appear when the welding temperature falls below about 300°C, and damage to tools occurs when it reaches about 200°C.

On the other hand, SSW creates a good welding surface free of defects even at around 150°C.

This means that FSW requires the temperature to be at least half the melting point (660°C), while SSW allows good-quality welding in the low temperature range.

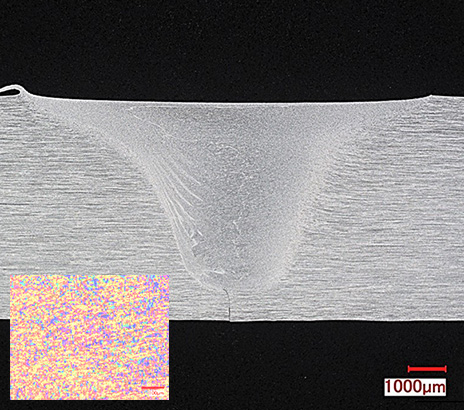

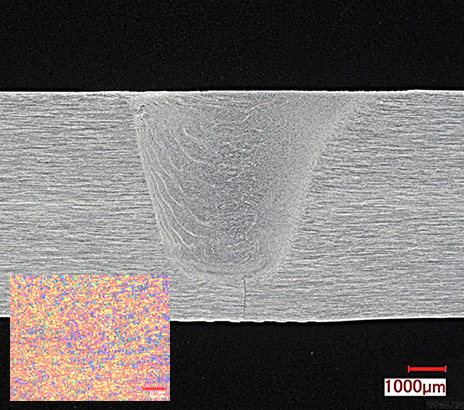

Cross-Sectional Features

FSW

SSW

Compared to FSW, SSW has a wavy-shaped stirred section, indicating more active plastic flow.

In the TMAZ (Thermo-Mechanically Affected Zone), the plastic flow zone is small, with a clearly defined boundary with the stirred section.

This shows that the plastic flow in the stirred section is amplified while the effect on other areas is suppressed.

Not only does this expand the range of possible welding conditions, but it also provides a number of advantages such as suppressing warping that occurs on the Advancing Side(AS) of the material part, suppressing excessive frictional heat, and suppressing deformation caused by downward force pressure on the material side.

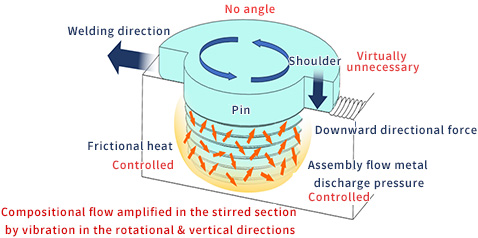

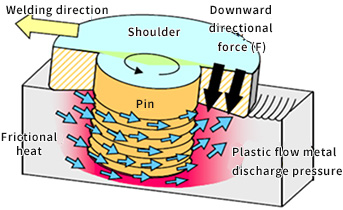

Welding Basic Principle

This newly invented principle as SSW (Synchronized Stir Welding) minimizes spindle load and vibrations on the main shaft, also minimizing temperature during the welding process, minimizing shoulder diameter without the need for a tilt angle or complicated spindle mechanism, which allows for a wide range of welding conditions, making it possible to perform high-strength welding free of defects.

RAM FORCE

Synchronized Stir Welding Solutions

- The tip of the welding tool is “driven with microwaves” in both the tool’s rotational and vertical directions.

- It passively syncs with the direction and speed required by the material to be stirred, smoothly stirring it in response to the movement needed for the material to be welded, thereby achieving a welding process that surpasses what had been possible until now.

conventional FSW

- Passive stirring by an external driving force

- Welding speed in a low speed range

- Large shoulder diameter is required

- High input heat

RAM FORCE-SSW

- Actively stirs the material in sync with the desired direction and speed

- Welding speed in a high speed range

- Small shoulder diameter

- Low input heat